|

The application of Dissolved Gas Analysis(DGA)

The fault free operation of power transformers is of major economic/safety importance to power utilities and industrial consumers of electricity. Dissolved gas analysis is an internationally accepted technique for fault identification while the transformer remains in service. The data supplied by dissolved gas analysis is a powerful tool for predictive maintenance.

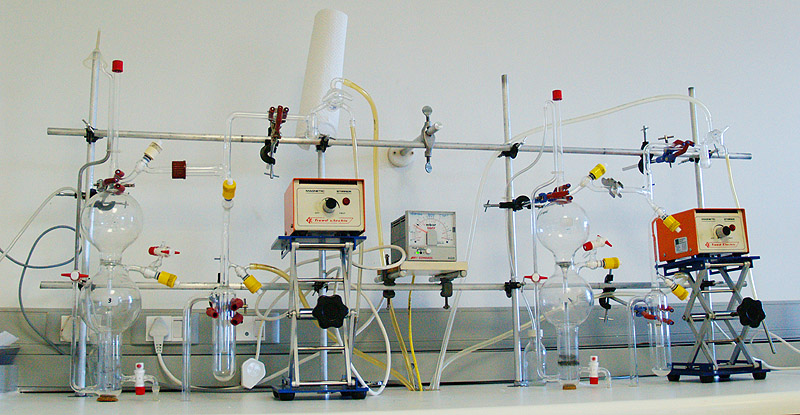

The insulating oil is capable of dissolving gases in the event of developing faults in the transformer. These gases are extracted from the oil and analysed by the sophisticated technique of Gas Chromatography.

Diagnosis methods are utilised to diagnose the type and severity of the fault occurring in the transformer.

GAS EVOLUTION DUE TO FAULTS IN THE TRANSFORMER.

Most faults that occur in transformer can be traced back to a few basic causes or phenomena namely

CONDITION KEY GASES

-ionising partial discharge(corona) Hydrogen (H2)

-low energy spark discharges Methane(CH4) Ethane(C2H6)

-severe local overheating Ethylene (C2H4)

-arcing or high current breakdowns Acetylene (C2H2)

-cellulose degradation Carbon Monoxide (CO)

These gases generated during a transformer fault are all combustible and lower the flash point of the insulating oil. In the event of a transformer fault, assuming the evolution of gases from below the oil, the force applied to the structure may approximate 360 PSI due to the steep wave front and high velocity, representing a loading sufficient to distort the container or shear the holding bolts and possibly cause a transformer oil fire.

Interpretation and Historical Data

TCS has one of the most comprehensive insulating oil data management systems and interpretation guide. This system does graphical trend analysis for gas-in-oil data. The reports contain recommended action based on the latest accepted guidelines and TCS's extensive experience. TCS will maintain all customers historical records. These data are used to update and improve the diagnostic process.

Results

All reports this included Graphs can be e-mailed to the customer i.e. full integration with Microsoft Office 2000.

Transformer Chemistry Services method of interpretation is based upon:

Key gases: CSUS values (Age compensated)

BS 5800/IEC 599 ratios (providing the Total Combustible Gases present are above 300 ppm)

Rogers Ratios

Trend (Production rates of gases) Morgan-Schaffer Tables

Total Combustible Gas Production Rates TDCG (c57.104-1991)

Total Combustible Gas Westinghouse Guidelines

Age of transformer.

History of transformer (Repaired, degasses, etc).

ADVANTAGE AND BENEFIT OF DISSOLVED GAS ANALYSIS (D.G.A.)

Ability to schedule outages for units in the warning stage (Minimise downtime: plan for most convenient time)

Possible mitigation of oil fires and consequential damage

Document first year in-warranty problems before out of warranty failure. As one example, GEGB has reported, "A number of faults have been detected, although in each case the transformer had satisfactorily passed the routine tests"

Reduce downtime cost for industrial units-emergency power or factory lay-offs, etc, and decrease insurance costs.

The D.G.A. technique detects newly formed faults both accurately and consistently, and will locate a fault that cannot be detected any other way. The growing importance of D.G.A. is demonstrated by increasing application

Monthly D.G.A of large power transformers (>300MVA) by National Grid UK

Recommended monthly sampling by American Nuclear Insurers

Numerous other Insurance Carriers

Virtually every recognized transformer authority

Clearly then, if owner/operators of large equipment have grown to depend on D.G.A. It follows that the same dependence should occur for medium power units (1-100MVA)

The difference would be the frequency of analysis

C.E.G.B (1974) reports over 90 % of transformers faults are detected by D.G.A. The estimated savings was between 1.5-3.0 million pounds per annum. Confidence in the method is now such that transformers are sent to works for repair and replaced by spares on no other evidence than that of D.G.A.

CIGRE REPORT 1984 states "Dissolved-gas-in oil chromatographic is successfully applied to fault detection in the maintenance of large power transformers. Savings achieved are in the 100 MILLION $ range

D.G.A. provides peace of mind for transformers owner/operators

|

|

FURAN TESTING

When the cellulosic insulation materials within a transformer undergo degradation some of the products formed are derivatives of the aromatic compound called furan. Furan is a heterocyclic aromatic system consisting of four carbons and one oxygen in a five membered ring with each of the carbons having a hydrogen attached; hence the molecular formula is C4H4O. The five most prevalent derivatives of furan that arise from the degradation of the cellulose and that are soluble in the oil to an appreciable degree are the following: 2-Furaldehyde; Furfuryl alcohol; 2-Acetylfuran;

5-Methyl-2-furaldehyde; and 5-Hydroxymethyl-2-furaldehyde.

The entire details of the procedure for determining the quantity of furanic compounds in an insulating fluid are given in the ASTM D 5837 method and are only briefly mentioned here. A sample of the oil is extracted with either another liquid such as acetonitrile or with a solid phase extraction (SPE) device. The extract is then analyzed using high performance liquid chromatography (HPLC).

The five furanic materials normally analyzed in this procedure are aromatic compounds that arise from the degradation of the cellulosic materials within a transformer either by normal aging or from being involved with an incipient fault. Thus the amount of these products present in the oil might be a good indication of the condition of the cellulosic insulation. At the present time there have been no limits or normal values established for these components either individually or in combination. Research is being carried out to find if there are any useful correlations that can be used but at the present it might only be useful to follow trends rather than absolute amounts in the oil. Another test that can be used to assess the condition of the cellulose within a transformer is to determine the average degree of polymerization. However, this is an intrusive test that requires a sample of the cellulose. One has to take the unit out of service to obtain the sample and a portion of the unit is destroyed in the process. If a good correlation can be found between the average degree of polymerization and the concentration of the furanic compounds either individually or in combination, then this would have a number of advantages for evaluating the condition of the cellulosic insulation within a unit. First it is a non-intrusive procedure. Second it does not require interruption of service to obtain a sample. Third the laboratory analysis requires less time and it is a more sensitive determination. Efforts are progressing toward this end.

|